|

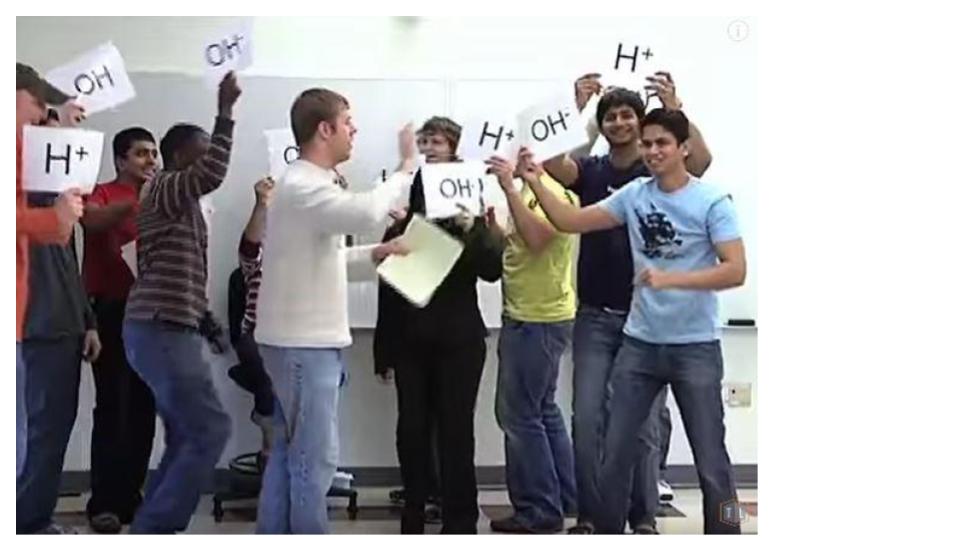

By Braden Boyd This article is part of our student collaboration series. What really happens when you add water to cement? In Dr. Tyler Ley’s educational production of “Hydration Theater”, he answers just that. Broken into five acts, this excursion into the molecular level of cement paste demonstrates what really occurs as cement is hydrated with water! It covers how this aqueous solution of cement and water react with one another in an exothermic way to give us what we know as concrete! The production also offers a fun way to teach those who view it about a critical step in theproduction of concrete. Inthe opening scene, the viewer's attention is captured and held by the enthusiasm of Dr. Tyler Ley and his students, as they convey the process of hydrating a cement grain on stage. Prologue - First Seconds The play opens with acement grain, C3S,that has not been hydrated. Aswater is added,and its molecules begin to tear at the cement grain. This attack frees Calcium Ions and Silicon Ions from the cement grain and releases them into the solution. TheOH-and the H+ in the water first reacts with the C3Sof the cement grain and then theC3Aand Gypsum and forms Ettringitein the solution. When thisoccurs, ions still collect and build larger and larger in the background. Act 1 Early age C-S-H emerges onto the stage to join the cement grain, forming around it as a kind of protective layer. This occurs due to the reactions of the ions that are still floating in the solution.The water molecules on stage then try and attack the cement grain again, but this time the C-S-H is there to defend it! The dense microstructure of the C-S-H makes it harder for water to reach the cement grain. Still, whilemost of the water molecules are kept out, some were still able to reach the cement grain. (#SAYNOTOH2O) Water molecules continue to try and attack the cement grain, reducing the heat of the molecules and releasing more and more ions.  Image 1: First physical change of the cement grain as it is hydrated by water. The image on the left represents the grain before hydration, and the right after hydration. Act 2 - Induction Period This act focuses onthecalcium ions in the solution and how they grow and buildhigher and higher in the solution. Then suddenly Calcium Hydroxide emerges on to the stage and breaks down the C-S-H molecules! This leavingthe cement grain open to a surge of attack from the water molecules. It is during this induction period that the cement is able to be place and worked before it begins to harden.  Image 2: Second physical change of the cement grain as it hydrated by water. The image on the left represents the hydrated cement grain, and the image on the right represents the grain after the ettringite has attached and extended out. Act 3 No longer having a layer of C-S-H to protect it, the cement grain begins to bebombarded by water molecules on stage. This leads to the heat of the particle increasing andcauses more C-S-H to form. Then the Ettringite, which had been floating in the solution,attachesto the surface of the C-S-H! TheEttringite then beginsto absorb water and extend out. This again changesthe physical layout of the cement grain, which along with the C3S of the cement grain, providestheinitial strength gain for the cement grain. Act 4 The cement grain has now grown dense from all the layers of CSH and ettringite that have formed due to the attacks from the water moleculesthrough the hydration process.The high density of these layers preventing the OH-and H+ of the water from reaching the cement grain. When the water molecules do reach the cement grain, the layersbecome even more densefrom the resulting reaction. This making it even harder forthe water molecules to reach thecement grain again.The reaction between the cement grain and the water is an exothermic reaction, so the cement grain begins to cool as it becomes harder and harder for the water molecules to reach it. Act 5 The reaction rate between the cement grain and the water moleculeshas come to an almoststandstill, as the water molecules are unable to reach the C3S inside the grain. Still,the water molecules continue to bombard the cement grain with attackson each side, trying to find a weak point in the structure. The hydrated cement grain withstood the attacks and repelled the water molecules. This is because the process of hydrating cement grains is a fusion controlled reaction. Still,a few of the sneakier watermolecules were able to find ways through the cement grain’s structure and reach the C3S inside. This process continues, and the cement grain again changes its shape, gaining the ability to have friction with other grains and provide true strength. Overall, I found the production of Hydration Theater to be both insightful and educational in how cement grains are hydrated. Theformat itself, aneducational theater production, was something I had not yet been introduced to, and I found it to be a very intriguing and fun way to learn. Dr. Tyler Ley and his enthusiastic cast truly capture the viewers’attention on stage through their enthusiasm as they transition from scene to scene. Through the cast and other means ways of representing cement grains, Dr.Tyler Ley has truly found aninventive and fun way to educate us all on what really happens when water is added to cement grains. I’m not alone in this opinion either! “Lovely.. expecting more learning videos.. we’re hungry bro”-Arasan K “This is a great way to learn about hydration of concrete. Highly recommended for anyone who wants a clear and basic understanding of the concept!”-ConcretePavements These comments are not alone in how many who have seen Hydration Theater feel! Fortunately, theplay has already made its way to video and has been made available to all through YouTube! Wouldn’t you like to be able to explain how hydrating cement really works? To learn what each molecule and charge does as a single cement grain is introduced to water in a fun and new way! Just as many others who have already caught this production, I recommend that everyone find a chance to view this educational production of “Hydration Theater”! Soon you too will be “hungry” for more productions just like it! #Hydration #Theater #HungryForKnowledge

0 Comments

Overview of the ATC If you’ve heard me talk recently, you have probably heard me mention the ATC, or the Autonomous Truck Corridor. This is an idea that I came up with by working with an awesome team at Oklahoma State, Penn State, and University North Carolina Charlotte. This is an idea that has infected my brain. I can’t get it out, and so I thought I would write a blog post about it. I also have some videos I have made about the concept at the end of the post. The US National Highway System (NHS) is critical for the efficient transport of goods and the safety and freedom of the traveling public. A special vehicle on the NHS is heavy freight trucks. Here are a few of the issues related to heavy freight trucks on the NHS:

Vehicle manufacturers are developing autonomous and electric trucks to address these needs but their limited haul distances and challenges interfacing with passenger vehicles have not allowed them to enter the market yet. If these needs are addressed it would create a monumental improvement in the US economy while improving the lives of the traveling public, and reducing the impact on the environment. I am part of a team of engineers who have a vision for a heavy freight truck corridor with a long life that uses autonomous, continuously powered, and electric heavy freight trucks. This corridor will be separated from passenger cars, specially designed for autonomous heavy freight trucks, and have an overhead electric power line to provide constant power. We call it the Autonomous Truck Corridor or ATC for short. Pretty cool name right? The ATC is a game-changer because the freight trucks can travel continuously without stopping, the vehicles can travel at higher speeds and at closer spacing, and the vehicles will be separated from passenger vehicles and so they can be autonomous. Batteries on the trucks will be charged so that they can remain powered once they leave the ATC to make local deliveries. This corridor will be largely built using existing right of way or it can be added as major highways are expanded. This will reduce land acquisition cost, allow freight to follow existing delivery lines, and leverage existing infrastructure. This will create unbelievable economic opportunities for the US. The ATC will reduce delivery times up to 50% while reducing traffic on existing highways. This reduction in traffic will improve diver safety and extend the life of existing roadways. The proposed electric motors are more energy-efficient and will reduce costs and emissions by > 25% per mile. A portion of these savings could be used to pay for the cost and maintenance of the ATC. Watch these videos if you would like to learn more about the ATC. References:

By Kristin Karleskint, Chad Staffileno, Michael Dickey, Zac Wilson, Alla Acheli, & Jon Choat This entry is part of our student collaboration series. What is porosity and how does it pertain to concrete? If you were told that a household sponge and a slab of concrete had anything in common, would you be surprised? At first glance, concrete appears to be an impenetrable solid, but in reality it’s porous much like a sponge! Porosity is a term commonly used in the concrete world and for good reason. This property refers to the amount and distribution of pores in the material. This description may present porosity as unimportant, but it actually controls many other significant concrete properties that determine the concrete’s durability! Properties including compression strength, tensile strength, flexural strength, modulus, resistivity, and permeability are all heavily influenced by the porosity. In general,when porosity increases, the strength decreases and the relative penetration increases. Both of these relationships are bad, meaning that these unseen pores could actually be detrimental to our concrete. Who would have thought that some holes in our concrete would play such a vital role in the lifespan of our infrastructure? In order to minimize our pores we must first understand how they develop and how to determine how many there are. There are three critical rules to determine the amount of pores in our cementand if used, secondary cementitious materials. These are the initial proximity of cement grains, the final proximity of cement grains, and the degree of hydration. All three of these rules are critical factors that determine the porosity of concrete and each will be discussed, coming up!

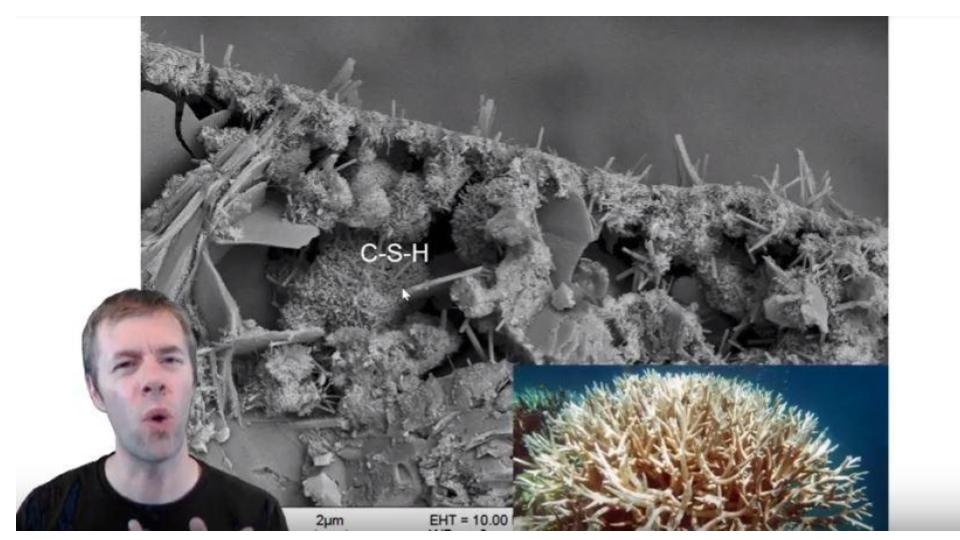

Rule number one: the initial proximity of cement grains. It’s important to note that idealized situationsare expressed in drawings to better demonstrate theseprinciples in the real world.These schematics are extremely helpful for you if you want to understand the big picture! However,you must keep in mind that they are based on THEORY. The drawing shown here represents how initial proximity contributes to strength of concrete, but it is idealized in the sense that cement grains are not always equally distributed and that the hydration products are not always the same length. Despite this, the drawing makes it obvious that the different water to cement ratios create very different load pathsand pore systems. Loads become easier to distribute when the path can spread out within the concrete. These load paths also act as barriers for fluid penetration, whichwill increase the durability of the concrete!What is even scarier is that cracks make this concept even worse. To learn more about cracks, Dr. Ley has several videos on his YouTube page. If you love concrete and you want it to last a long time, then this information should be exciting! This concept can be defined as tortuosity, and when a system is more torturous it becomes more durable. By Erin McArtor This article is part of our student collaboration series. Have you ever wanted to know what cement does after water has been added to it? Well, this is the video for you! In this video, Dr. Tyler Ley delves deep into the cement hydration process, with a step-by-step break down of what goes on inside the concrete.Concrete is made of rock, sand, cement, and water. All aspects of concrete are important; however, the cement and the water are what make the magic happen. In Portland Cement, there are compounds present before hydration, and other compounds that are formed after hydration. As you may already know, un-hydrated Portland Cement contains C3S (Alite), C2S (Belite), C3A (Aluminate), C4AF(iron), Gypsum, and Limestone. This video introduces the more unknown compounds that are found in hydrated Portland Cement,what each of them provide to the cement, and how each of them are related to the Avengers. Crazy, right? The first compound Dr. Ley introduces is Calcium Silicate Hydrate, also known as C-S-H (C-S-H! C-S-H!). It is formed from the reaction of C3S and water, and it gives hydrated Portland Cement its strength.C-S-H can also be developed in other ways. Pozzolans, such as Class F Fly Ash consume CH (another hydration compound) and convertit to C-S-H. The relationship between concrete and C-S-H. It is very similar to the relationship between Thor and his hammer; without his hammer, Thor has none of his “God of Thunder” powers and is basically just a normal Asgardian. You might ask yourself, “hey, what about in Thor Ragnarok where he basically becomes lightning, right?” Well we are not considering that for this example. However, great action films aside, without C-S-H, the concretewill lackstrength.It also keeps the “outside nasties” out of the concrete. C-S-H is also known for its shape-shifting abilitiesalso very hard to characterize because its structure and chemical composition changes depending on when, how, and under which situation it is formed and looked at. It does not have an ordered structure, so it is always changing its structure and chemical composition depending on when and how it is looked at. Shown below is an image of magnified C-S-H.

By Chad Staffileno, Kristin Karleskint, Michael Dickey, Zac Wilson, Alla Acheli, Jon Choate This entry is part of our student collaboration series. Have you ever seen concrete that is cracking, shrinking, or even falling apart? A large part of why this happens is due to the pore structure in our concrete. A pore is basically a void inside concrete. Think about a sponge, you will see all the gaps and holes. That is pore. If we can control the pore structure to help reduce cracks and permeability of our concrete, we will create durable long lasting structures that will last generations. In order to understand why the pore structure of our concrete is so important, we first must take a look at the types of pores that actually form in concrete. In a typical mixture there will four different types of voids. From smallest to largest, there is CSH interlayer space, Capillary pores, entrained air, and entrapped air. The CSH interlayer pore is the space between the CSH particles. This space really cannot be avoided because there are formed during the creation of CSH and do not affect the concrete as much. These voids are really small, about .5-2.5nm and really do not affect the permeability or strength of the concrete. Next is what we call capillary voids, these pores are the space between the cement grains themselves, usually about 2.5nm -5μm in diameter. To compare these to the CSH voids imagine that you are at a crowded bar. The space between your fingers, arms, and legs would be the CSH interlayer space and the Space between another person and you would be capillary voids. The volume of these voids is largely dependent on the water-to-cement ratio(w/c), and the degree of hydrationand other factors talked about in other videos.If you know how to control these pores you can have better control of the creep, shrinkage, andpermeability and other properties of your concrete. The next pore is an air entrained void which is actually formed by putting a soap like material called a surfactant (air entrainer) into your concrete mixture. These voids are generally 10μm –to 1mm in diameterand actually have a distinct spherical shape. The construction industry refers to this add mixture as adding “air” into your concrete. The reason we add air into the concrete is to get good freeze-thaw durability. Finally, we have entrapped air which is air that naturally gets trapped in your concrete while mixing. These entrapped pores are usually larger the 1mm. All of thesevoids can contain water, air, or both depending on the conditions your concrete is in. Having pores in your concrete can both help and hurt your durability which no one wants. If you have too many poresthat are interconnected, this allows outside chemicals to penetrate your concrete which can over time decrease the structural integrity of your concrete

|

Join the Concrete Freaks email list and receive exclusive tools, tips, and resources directly from Tyler.

Click Subscribe. AuthorDr. Tyler Ley, Ph.D, P.E., is a professor of structural engineering at Oklahoma State University. He was named a Most Influential People in the Concrete Industry by Concrete Construction Magazine in 2019, and was named the outstanding professor at a research university by the Oklahoma Foundation of Excellence in 2018. He has a passion for researching and educating people about what he considers to be the greatest material in the world. CategoriesArchives |

- Tyler Ley

- Research

- Publications

- Labs & Facilities

- YouTube

- Giving

-

Additional Sites

- Group Members

- Fly Ash Calculator

- Shirts

- Super Air Meter

- Engineering is Everywhere

- Hydration Theater!

- PLC

- Precast Overhang

- Tarantula Curve

- TarantulaVideos

- Troubleshooting videos

- E2 videos

- Blog

- Reinforcing Secrets

- Myers Briggs

- mix design YouTube

- Curing Videos

- Specifications

- ATC

- fly ash video

- ACI member

- Job

- sustainability

- Minnesota

- Rapid Repair

- Dreamcrete

- teams

- SAM

- Phoenix

- Tools

- Air loss during pumping

- WOCwater

- Tyler Ley

- Research

- Publications

- Labs & Facilities

- YouTube

- Giving

-

Additional Sites

- Group Members

- Fly Ash Calculator

- Shirts

- Super Air Meter

- Engineering is Everywhere

- Hydration Theater!

- PLC

- Precast Overhang

- Tarantula Curve

- TarantulaVideos

- Troubleshooting videos

- E2 videos

- Blog

- Reinforcing Secrets

- Myers Briggs

- mix design YouTube

- Curing Videos

- Specifications

- ATC

- fly ash video

- ACI member

- Job

- sustainability

- Minnesota

- Rapid Repair

- Dreamcrete

- teams

- SAM

- Phoenix

- Tools

- Air loss during pumping

- WOCwater

RSS Feed

RSS Feed